Precision Quality Lab

Precision and Reliability

in Every Component

At Maquinados Libra, we rely on a team of specialized metrologists certified by companies such as Mitutoyo, along with industry-leading instruments that ensure accuracy in every inspection process.

Our metrology infrastructure includes:

- Hexagon Coordinate Measuring Arm

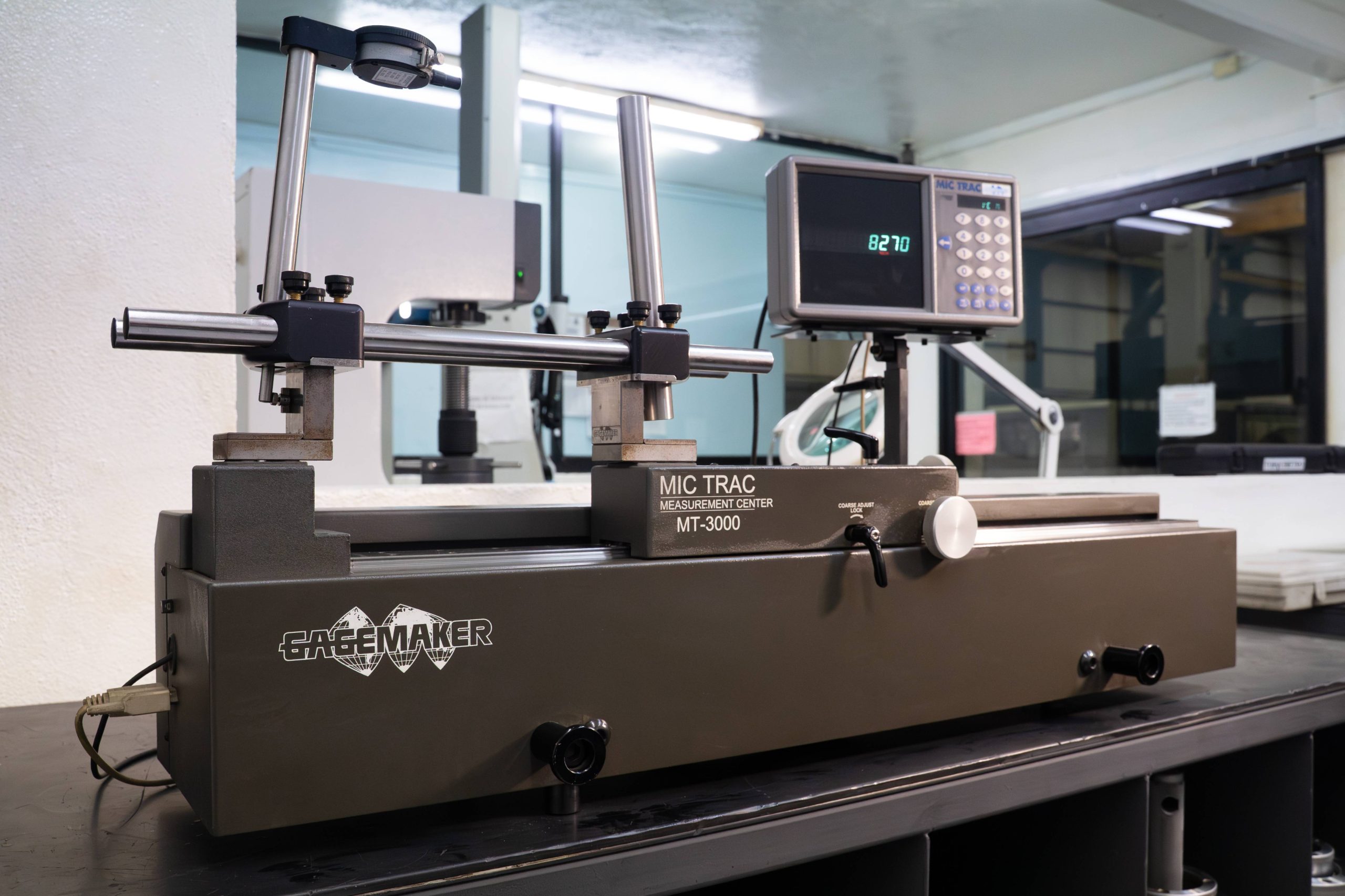

- Mick Trac MT-3000 (up to 24”) for instrument setup and calibration

- Mitutoyo Granite Surface Plates

- Complete Gage Maker instrument set for standard threads (UN, UNC, Acme, Stub Acme) and oilfield threads (8Rd, Buttress, IF, Regular, etc.)

- Gauge Blocks

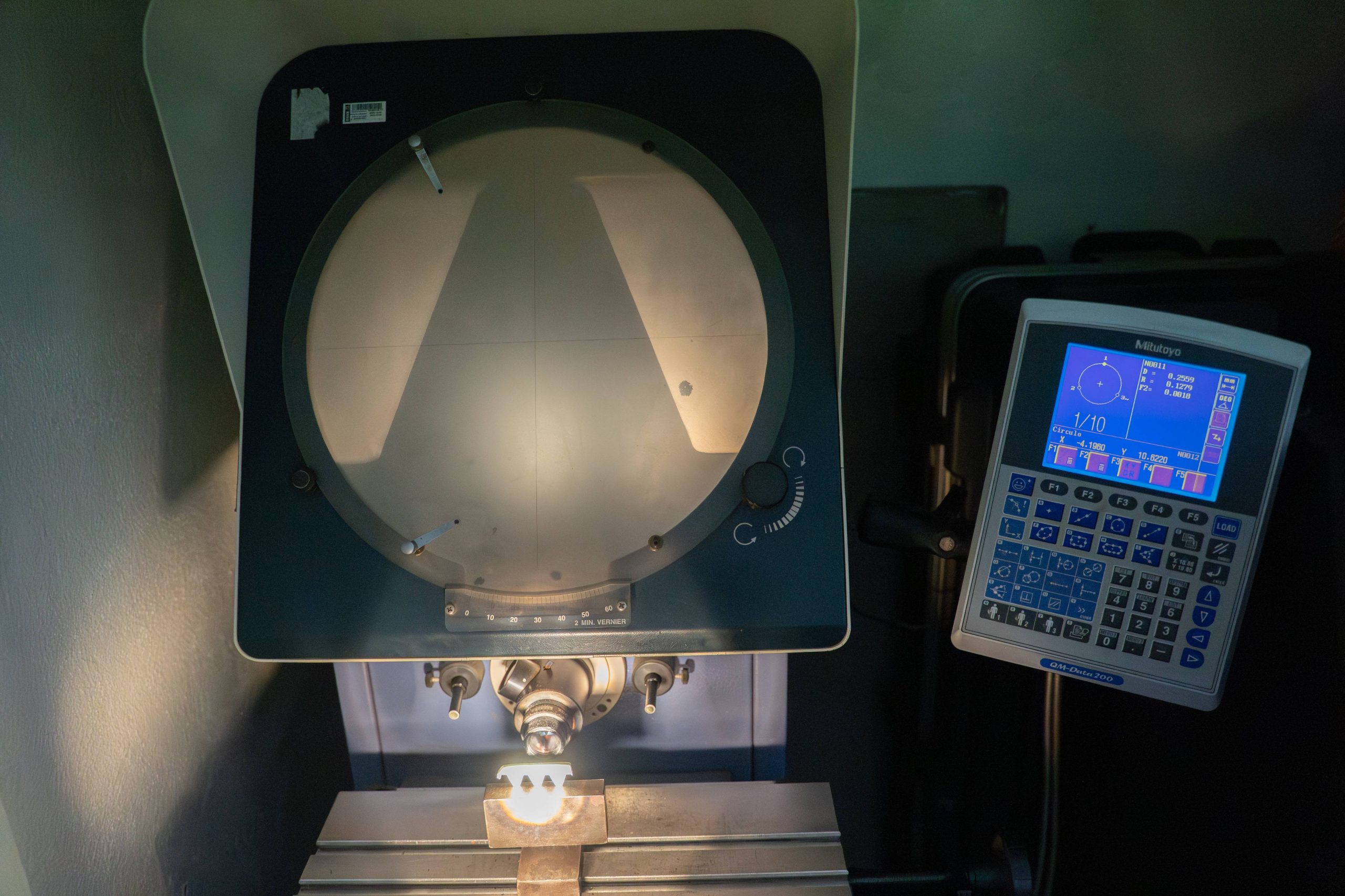

- Mitutoyo Optical Comparators: PH-A14 and PH-3500

- Bore gages with ten-thousandth resolution (diameters up to 30”, length 50”)

- Outside micrometers with ten-thousandth resolution (diameters up to 24”)

- Rockwell C Hardness Tester

- Surface Roughness Tester

Digital & CAD/CAM Support

We use integrated design and manufacturing software that enhances the inspection workflow and ensures precision from the initial model to the final delivery:

Autocad

Computer aided design

Mastercam

Computer-aided manufacturing

Excellence in Every Detail

At Maquinados Libra, quality is the foundation of everything we do.

Our Quality Laboratory ensures the precision, traceability, and reliability of every component we manufacture—meeting the highest international standards and guaranteeing consistent performance.